Produse Bucket Elevators

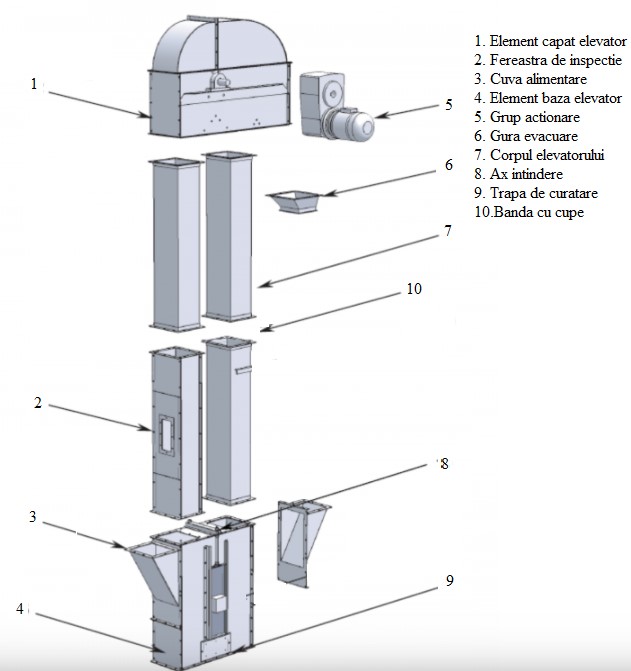

The bucket elevator is a piece of equipment that provides vertical transportation of granular materials. The transported material is placed in the receiving hopper at the base of the elevator and is taken up by the buckets. Once lifted to the desired level, the material is discharged from the buckets through the discharge mouth under the elevator head.

The choice of buckets, the belt and lifting speed of the elevator depends on the required production capacity and the type of product to be transported. Capacity is influenced by the type, particle size, and moisture content of the product.

Typically, the base of the elevators is installed below ground level, in a receiving pit.

The electric motor with a gear unit and pinions is mounted on the head of the elevator. The gear unit’s role is to reduce the motor shaft’s rotation speed to match the peripheral speed of the drive drum, which must be equal to the transport speed. The electrical power is determined based on the required transport capacities and the material’s characteristics or the height of the elevator.

These pieces of equipment are sized considering the characteristics and quantities of the material to be transported, the needs of the customer, and the site conditions. We suggest getting in touch with an ALWO consultant who will help you obtain the necessary equipment tailored to the application’s needs and requirements.

Produt image caption:

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy