Produse Overhead Conveyors

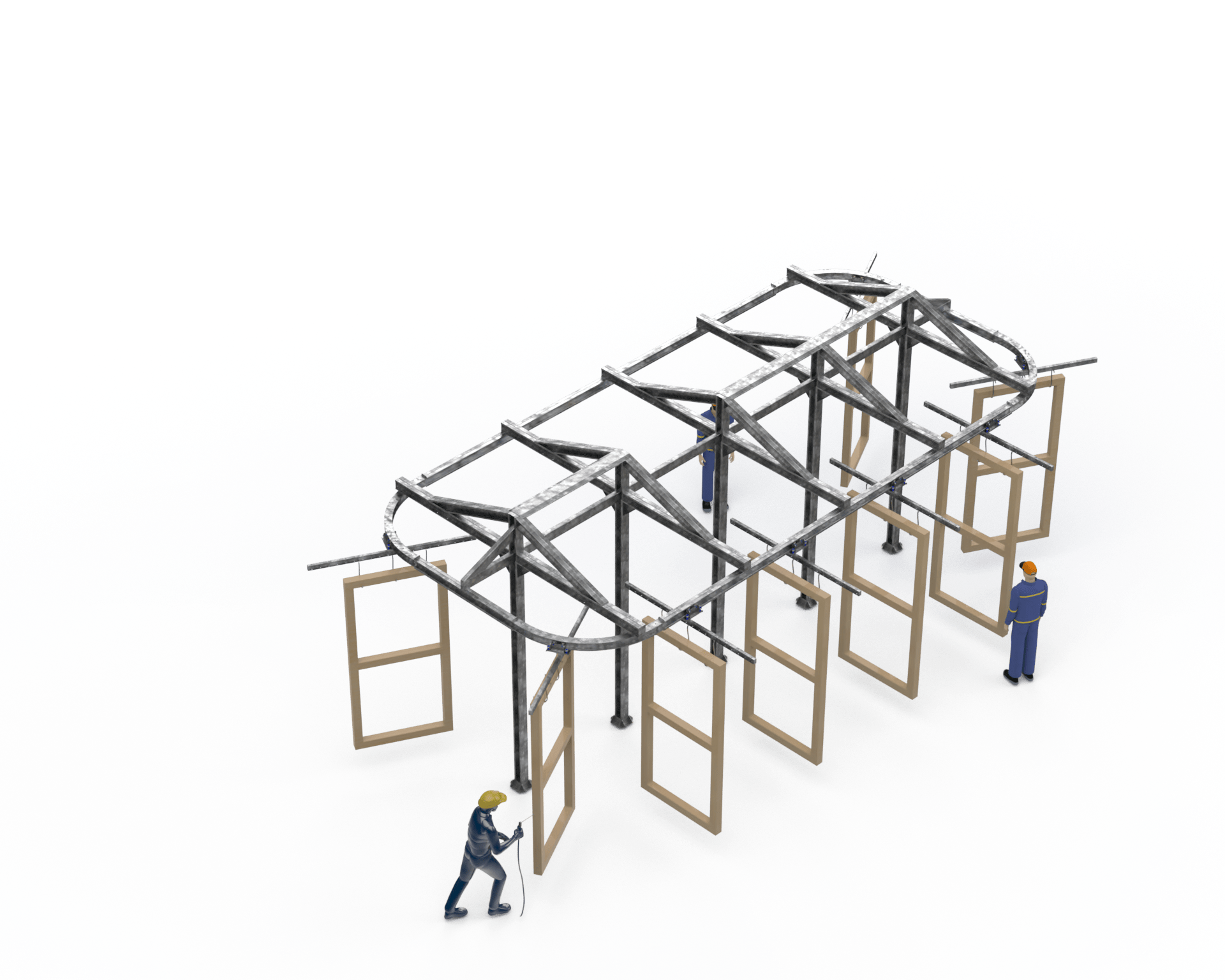

These types of units are recommended for mass production manufacturing and are optimized for the most common tasks: finishing or assembly/preassembly. They can be slightly modified depending on the application, its use ranging from the metalworking industry to the wood industry, the automotive industry and so on.

They are ideal for the mass production of doors, windows, metallic frames, chairs or any other components, assemblies or subassemblies, which require operations such as prepping, finishing or assembling.

These units are modular and usually manufactured out of pressed and welded steel. The path of the conveyor belt can be simple or complex, with upward or downward slopes and multiple direction changes. Moreover, the length of the conveyor can vary depending on the number of operations required on the production line, such as assembling, surface prepping, applying paint, polymerizing, drying and so on.

These conveyors can be ordered with either manual traction or with a gear motor. Depending on the complexity of the application, the conveyor can be fitted with either a simple or a complex automatization system. The belt itself can also be fitted with position sensors, a speed adjustor, “abandoning” lines, a rotation/lifting/decoupling system and much more, depending on your needs.

Some advantages of this type of conveyor are:

– Easy installation and operation;

– Low energy consumption;

– Very high transporting capacity on the same conveyor (t);

– Easy transportation (without shocks) for very heavy objects;

– Continuous operation 24/7;

– Easy maintenance and upkeep;

– Suitable for all industries;

– Ideal choice for facilitating and improving the technological flow.

This equipment is personalised for every situation and use the customer requires. As it is not a standardised product, we suggest contacting an ALWO consultant in order to find the best solution for your needs.

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy