Consulting has nothing to do with believing. Consulting is based on knowledge, planning, and experience. The problems you encounter and the questions you have can find solutions and answers by contacting our consultants. Our vast experience accumulated over the years allows us to quickly develop an idea of the situation you present to us.

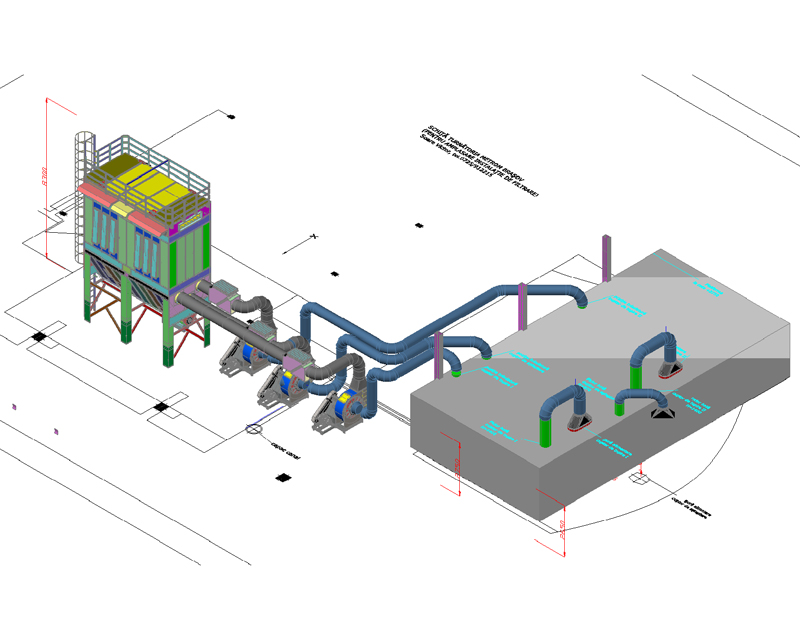

Also know that we are not alone! We are constantly assisted by modern CAD/CAM programs (SOLIDWORKS, AUTOCAD, CAM SOFTWARE, etc.), which allow us to virtually simulate all possible real situations, offering only the solutions that work. ALWO seeks to develop new solutions and improve the equipment it produces, and thanks to its customers and collaborators, it accumulates ‘Know-How’ from every situation encountered.

As specialists in the field, the ALWO team offers consulting services in the sphere of industrial air purification to all its partners. In this regard, you will receive competent information to help you make decisions regarding:

ALWO’s design engineers always ensure the best connection with clients, providing both high-level design and design of standard equipment, as well as personalized equipment and installations that meet the client’s needs to the maximum. Ongoing communication with both clients and colleagues from the execution/production departments, as well as with those from the Assembly/Commissioning departments, leads to a constant improvement of products and services, bringing the equipment offered to the client to a level that meets both functional and ease of maintenance.

Sizing equipment, their placement, ductwork, and utilities routes make the work of ALWO’s designers a major benefit offered to customers, often free of charge

ALWO equipment manufacturing takes place in modern production facilities equipped with CNC (Computer Numerical Control) machinery, ensuring the precise execution of components designed by our engineering team. The raw materials and materials used are of the highest quality, certified by the experience of well-established partners in the Western European market. A quality management system based on ISO 9001:2015/ISO 9001:2015, 14001:2015/ISO 14001:2015, and 45001:2018/ISO 45001:2018 certification ensures that all equipment delivered by ALWO meets the highest standards, complying with all European Union regulations and requirements.

The shipping department consistently ensures complete and high-quality delivery, providing all the documentation accompanying the equipment in accordance with legal requirements.

Our company offers its clients the advantage of turnkey installations, with specialized technicians in assembly and commissioning providing customers with all the necessary technical support to put ALWO equipment and installations into operation. Individual equipment, of lower complexity, that allows for assembly by the customer, is delivered with complete documentation and assembly diagrams to facilitate the installation.

With nearly 20 years of experience in sheet metal processing, it’s time to introduce you to all the services we offer. We have launched a new website dedicated to ALWO’s complementary services, www.prelucrare-tabla.ro, where you can find all the necessary information and get inspiration for future projects!

When it comes to processing a tough material like metal, advanced equipment and well-trained professionals are needed to streamline all processes and achieve results in line with clients’ expectations. At ALWO, we have everything we need to provide sheet metal processing services such as laser cutting, Abkant bending, welding, electrostatic field painting, Autocad and SolidWorks design, and decorative panel production.

Laser Cutting

The most advanced method of cutting profiles and geometric shapes in steel, aluminum, or stainless steel sheets is possible with the help of Bystronic BySmart Fiber 3015 and Bystar 4020 3.5 kW equipment. Although we can laser-cut sheets up to the standard size of 4000 x 2000 mm, the maximum thickness of the sheet varies depending on the material it is composed of, from steel (20 mm) to stainless steel (10 mm) or aluminum (8 mm).

Abkant Bending

For this process, we use Bystronic 170 Tf x 3000 mm, Trumpf 170 Tf x 4000 mm, and Yawi 300 Tf x 4000 mm machines. We can perform bends at almost any dimensions, thanks to various dies and knives. The material processing speed is high, allowing us to maintain a constant flow and meet the most specific requirements.

Welding

Our staff is prepared for any challenge, and with the help of a Motoman EH80 robot, we perform precision work at high speed. We weld TIG/WIG and MIG/MAG, thus catering to most customer needs. All our projects are supervised by a qualified coordinator, and we guarantee 100% quality in the welding processes.

Decorative Panels

Whether you already have an idea or need inspiration, we can help you anytime with decorative panels for gardens or for cladding balconies and stairs. On http://www.prelucrare-tabla.ro, you can find a small part of the models available in our library, along with all the details on how to contact us when you need additional information. Due to our experience, ultra-performing equipment, and qualified staff, creating personalized designs is easily achievable for us.

Powder Coating in Electrostatic Field

Dry paint particles are applied using an electrostatic field without the use of hazardous chemicals. After the powder application, the pieces are placed in an oven at temperatures of 180-200°C to be polymerized. The dimensions of the ALWO oven are 3000 x 7000 x 2500mm (l x W x h), so we can say that the options are not limited at all.

Autocad & SolidWorks Design

We use Autocad and SolidWorks to streamline design and documentation workflows. Therefore, you can be assured that our projects are created by professionals, optimized, and also creative.

We welcome you anytime at www.prelucrare-tabla.ro! If you need additional information or want to share your ideas, feel free to email us at comercial@alwo.ro or call us at +40756 137 333.

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy