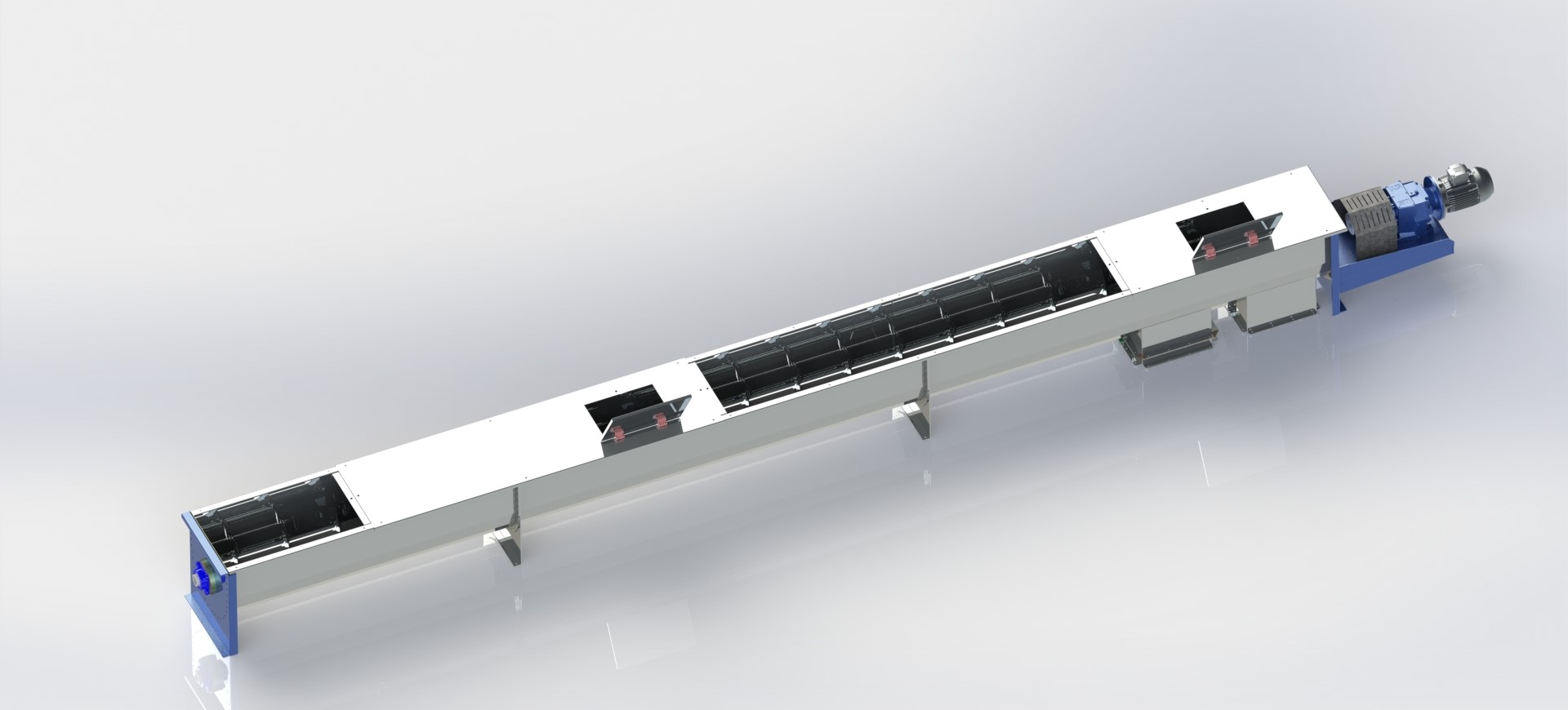

Produse Scraper Conveyors (Redler Type)

Chain and scraper conveyors are a continuous action equipment that uses scrapers to transport bulk materials. These scrapers are attached to the chain and immersed in a bulk material layer for the purpose of transporting it.

REDLER type scraper conveyors are used for moving small-sized, granular, or bulk materials such as sawdust, residues, grains, seeds, or other materials. This type of conveyor is widely used in the wood, metallurgy, chemical, agriculture, mining, construction and many other industries.

The conveyor is a rectangular metal structure made up of homogeneous components. The element in continuous motion is the chain to which the scrapers are attached, moving the material.

The conveyor provides loading and unloading ports. The latter is done through the lower part of the metal structure. The dimensions of the transported material should not exceed 15-30mm, and the temperature should not exceed 150°C.

The length of the conveyor is determined based on the individual needs and preferences of the customer. Scraper conveyors can be designed for horizontal or inclined material transport, up to an angle of 45°.

The advantages of scraper conveyors are:

These pieces of equipment are sized considering the characteristics and quantities of the material to be transported, the needs of the customer and the site conditions. We suggest getting in touch with an ALWO consultant who will help you obtain the necessary equipment tailored to the application’s needs and requirements.

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy