Produse SFPJ FILTERS – ALWO PULSE JET FILTERS

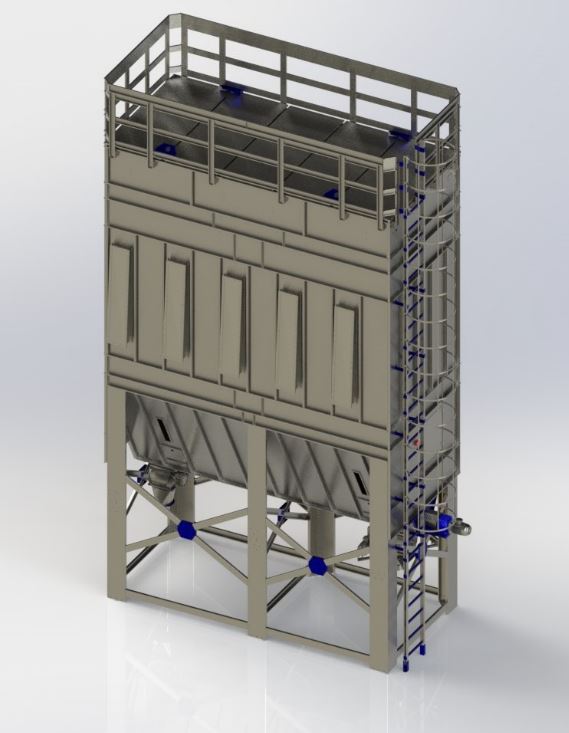

The ALWO Pulse-Jet Filters are external filters designed for dust retention, utilized in a wide range of applications, with various types of filtering materials. It is the ideal filtering equipment when you own a large amount of industrial equipment that generate large quantities of dust of different types and characteristics.

Due to its many filtering sleeves, the ALWO Pulse-Jet can take in high flows of stale air (up to hundreds of thousands cubic meters per hour) and it is recommended as the best filter for continuous operation 24/7. The collection and dust extraction system can vary depending on the particular use or upon the request of the customer.

The ALWO Pulse-Jet is one of the most reliable equipment for dust retention and provides a great deal of advantages:

In accordance with ATEX rules and regulations, the ALWO Pulse-Jet can be fitted with safety sensors and an anti-explosion system, such as the following:

Dust collection can be achieved either in metallic bunkers situated at the bottom of the filter tank or through an automatic extraction system located inside the filter tank, which consists of a damper and a dosing valve.

The automatic extraction system ensures a constant unloading quantity of retained dust and a constant pressure inside the filter, unloading taking place as the filter is running.

| CODE | No. of filters | Filter diameter | Filter height (mm) | Station length (mm) | Station height (mm) | Filtering surface (m²) | Crossing speed

(m/s) |

Expected flow (m³/h) | No. of solenoid valves 24 VAC |

| SFPJ 2.4/125*3/142 | 120 | 125 | 3000 | 2000 | 7500 | 142 | 0.03 | 15500 | 10 |

| SFPJ 2.4/125*3/212 | 180 | 125 | 3000 | 3000 | 7500 | 212 | 0.03 | 23000 | 15 |

| SFPJ 2.4/125*3/283 | 240 | 125 | 3000 | 4000 | 7500 | 283 | 0.03 | 31000 | 20 |

| SFPJ 2.4/125*3/354 | 300 | 125 | 3000 | 5000 | 7500 | 354 | 0.03 | 38300 | 25 |

| SFPJ 2.4/125*3/424 | 360 | 125 | 3000 | 6000 | 7500 | 424 | 0.03 | 45800 | 30 |

| SFPJ 2.4/125*3/495 | 420 | 125 | 3000 | 7000 | 7500 | 495 | 0.03 | 53500 | 35 |

| SFPJ 2.4/125*3/567 | 480 | 125 | 3000 | 8000 | 7500 | 567 | 0.03 | 61300 | 40 |

| SFPJ 2.4/125*3/636 | 540 | 125 | 3000 | 9000 | 7500 | 636 | 0.03 | 68700 | 45 |

| SFPJ 2.4/125*3.5/165 | 120 | 125 | 3500 | 2000 | 8000 | 165 | 0.03 | 17900 | 10 |

| SFPJ 2.4/125*3.5/248 | 180 | 125 | 3500 | 3000 | 8000 | 248 | 0.03 | 26800 | 15 |

| SFPJ 2.4/125*3.5/330 | 240 | 125 | 3500 | 4000 | 8000 | 330 | 0.03 | 35700 | 20 |

| SFPJ 2.4/125*3.5/412 | 300 | 125 | 3500 | 5000 | 8000 | 412 | 0.03 | 44500 | 25 |

| SFPJ 2.4/125*3.5/495 | 360 | 125 | 3500 | 6000 | 8000 | 495 | 0.03 | 53500 | 30 |

| SFPJ 2.4/190*3.5/585 | 420 | 125 | 3500 | 7000 | 8000 | 577 | 0.03 | 62400 | 35 |

| SFPJ 2.4/125*3.5/660 | 480 | 125 | 3500 | 8000 | 8000 | 660 | 0.03 | 71300 | 40 |

| SFPJ 2.4/125*3.5/742 | 540 | 125 | 3500 | 9000 | 8000 | 742 | 0.03 | 80200 | 45 |

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy