Produse Fog Retention Equipment

This category of equipment is intended for the metalworking industry, during the classic processes of obtaining final parts, such as milling or woodturning, when oil or water-based emulsions are used.

The use of these emulsions leads to the formation of vapors and mists which, in the end, reach the atmosphere of the production space. High concentrations of these emulsions have a detrimental effect on health when inhaled. Nonetheless, there are also economic reasons for the use of fog retention equipment. Even in a well-ventilated environment, emulsions dissipate, thus being necessary to refill the tanks of the machine tools to continue their mechanical processing. It is easy to quantify the annual amount of emulsion consumed and implicitly the acquisition costs.

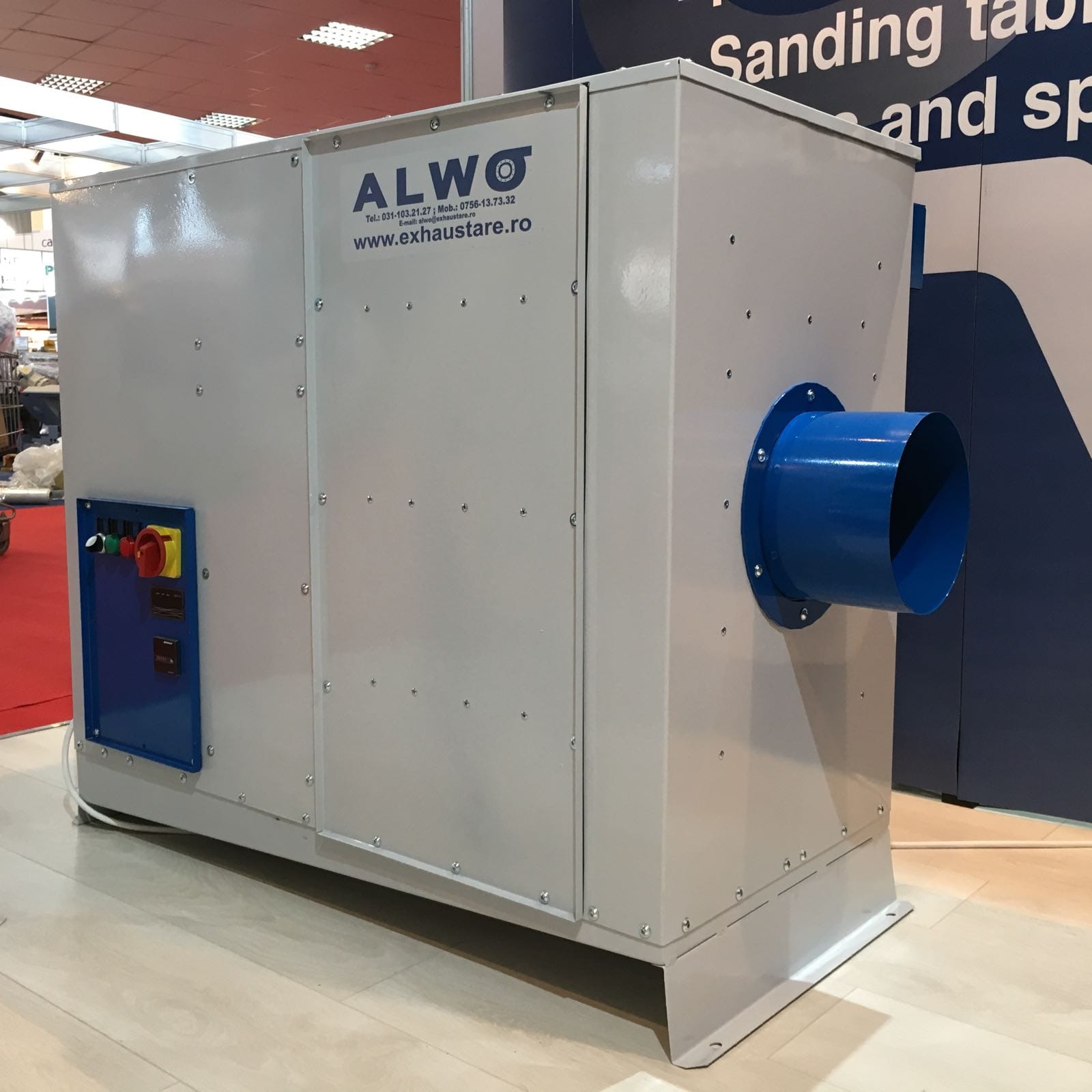

The vapors / mists formed reach liquid state again with the help of fog retention equipment, which makes use of the coalescence effect (the fusion of vapors and the formation of liquid droplets through the filter mediums inside the filter).

A series of filter mediums which have the property of self-drain are installed inside the equipment. The tank in which the liquid accumulates is equipped with either a drain valve or a system for automatic reintroduction of solution into the tank of the equipment.

Depending on the number of machine tools and their type, solutions can be varied, from installing a local equipment serving a single machine, or centralized installations equipped with storage tanks and liquid distribution pumps for each work machine.

Absorption of the contaminated air is made from the machine’s cabin, where the part is processed and the emulsion jets are applied, creating fog.

These fog retention machines can be equipped with either disposable fiberglass filters or metallic filters that can be cleaned with industrial cleaning solutions. In order to reach the highest level of filtration, they can also be equipped with HEPA filters.

In case of oil mist, a filtration equipment with electrostatic batteries is recommended, which can be cleaned after certain time periods. They can also be equipped with HEPA filters, installed after the electrostatic batteries.

Our Fog Retention Filters can be equipped with filter replacement and filter cleaning warning systems, but also with an automatic start/stop system. Together with the equipment it serves, an automatic liquid reintroduction system for the work machine tank or inverter for adjusting the absorbed air volume can be introduced, and depending on the customer requirements, customized solutions can also be found.

cu expertiza vasta

ISO 9001:2016

din 1999

© 2000 – 2024 Alwo Therm.

Privacy Policy | Cookie Policy